FROM THE VINEYARDS TO THE BOTTLE

The Cellar

The cellar is where the grapes are received, fermented in steel tanks, aged in concrete tanks and bottled.

Selection

The grapes are harvested by hand, placed in 18 kg boxes and taken to the cellar where a second quality check and careful selection is carried out.

Vinification

The vinification takes place almost exclusively in temperature-controlled stainless steel tanks, in order to have better control over alcoholic fermentation and maceration, also thanks to process automation.

Aging and Maturation

Our fine red wines, after fermentation, mature in wood.” The “Campi Taurasini,” “Taurasi,” and “Taurasi Riserva” are aged partially in 225-liter French oak barriques and partially in large French and Slavonian oak casks of 30 hectoliters.

The aging period in wood varies from 12 to 18 months depending on the type and vintage. In wood, the wine matures and evolves through micro-oxygenation, enhancing its bouquet and naturally stabilizing its color.

The quality, selection, and type of wood are fundamental. For this reason, we work and collaborate with the finest cooperages and the most renowned European master coopers.

Storage

After fermentation and wood aging, our red wines rest in concrete tanks for several months or even years before bottling.

Concrete allows the wine to stabilize and slowly refine with the aim of achieving greater finesse, elegance, and organoleptic complexity.

The decision to vinify the grapes from our oldest vineyards separately and create a wine following the oldest tradition has led us to use amphorae as a tool for vinification and aging of the wine.

We use handmade clay and ceramic amphorae that offer controlled micro-oxygenation. We use handmade clay and ceramic amphorae that offer controlled micro-oxygenation. The result is a more fruity and authentic wine that maintains a natural full-bodied structure.

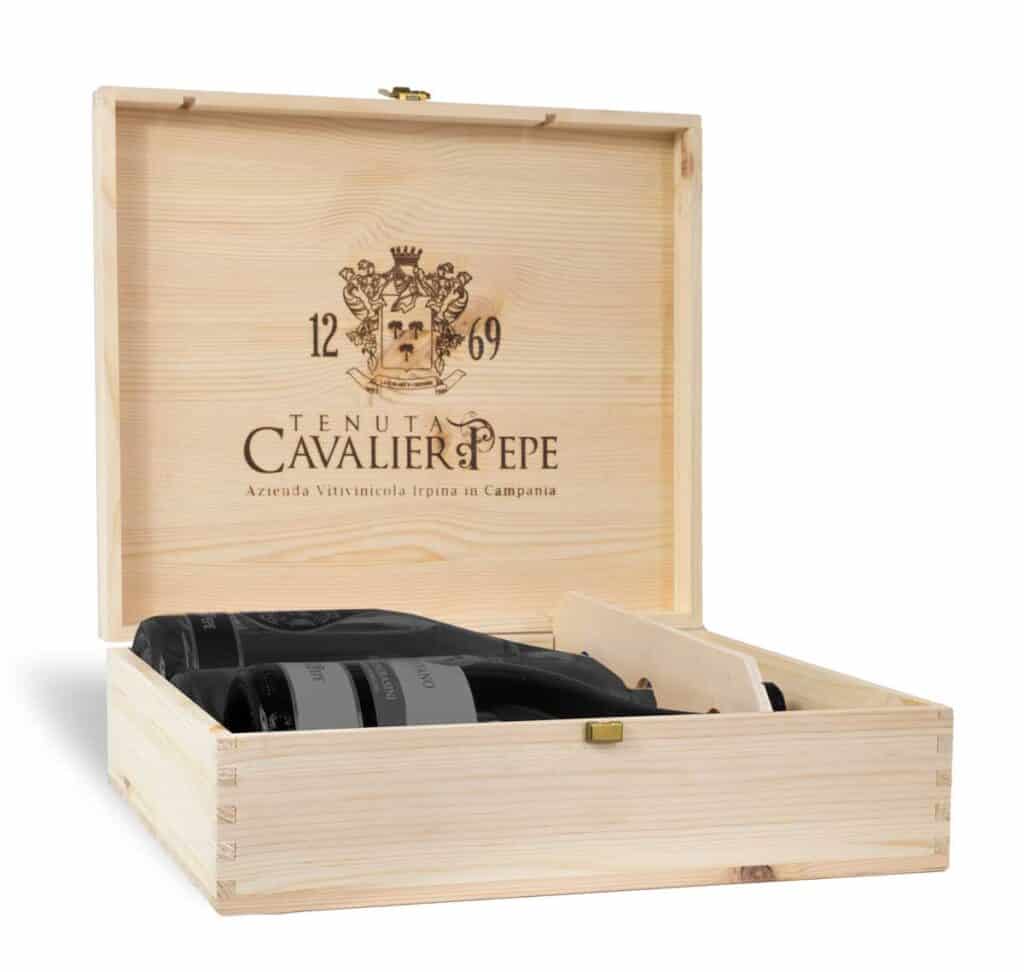

The bottling room

The most technologically advanced room in the cellar consists of state-of-the-art machines.

Our bottling line is divided into two sections. The first part includes the filtration unit, filler, and capper, while the second is dedicated to packaging with the washer-dryer, labeler, capsule applicator, and cartoner.

Each of these machines requires skilled hands to control, clean, and care for every detail to preserve the quality of the wine and its presentation.

Internal Laboratory.

Our laboratory allows us to control and monitor the entire production process step by step, from grape analysis to those in fermentation and aging, all the way to bottling. The analyses are essential for us; they support us during weekly tastings and enable us to meticulously track the evolution of the wines.